Search

SpaceX Starship (spacecraft)

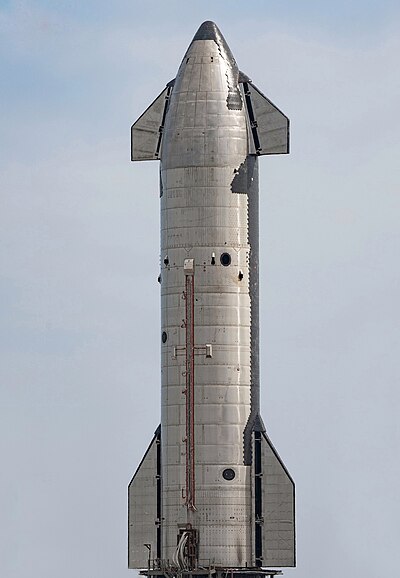

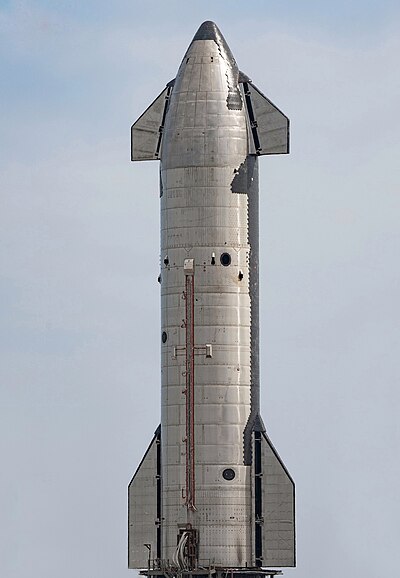

Starship is a spacecraft and second stage under development by American aerospace company SpaceX. Stacked atop its booster, Super Heavy, it composes the similarly named Starship super heavy-lift space vehicle. The spacecraft is designed to transport both crew and cargo to a variety of destinations, including Earth orbit, the Moon, Mars, and beyond. It is intended to enable long duration interplanetary flights for a crew of up to 100 people. It will also be capable of point-to-point transport on Earth, enabling travel to anywhere in the world in less than an hour. Furthermore, the spacecraft will be used to refuel other Starship vehicles to allow them to reach higher orbits and other space destinations. Elon Musk, the CEO of SpaceX, estimated in a tweet that 8 launches would be needed to completely refuel a Starship in low Earth orbit, extrapolating this from Starship's payload to orbit and how much fuel a fully fueled Starship contains. To land on bodies without an atmosphere, such as the Moon, Starship will fire its engines and thrusters to slow down.

Development began in 2012, when Elon Musk described a plan to build a reusable rocket system with substantially greater capabilities than the Falcon 9 and the planned Falcon Heavy. The rocket evolved through many design and name changes. On July 25, 2019, the Starhopper prototype performed the first successful flight at SpaceX Starbase near Boca Chica, Texas. The SN15 prototype became the first full-size test spacecraft to take off and land successfully in May 2021. On April 20, 2023, Ship 24 and Booster 7 lifted off the pad, the first time the booster and Starship flew together as a fully integrated stack. On November 18, 2023, Ship 25 and Booster 9 launched, successfully completing hot-staging, during the launch, Ship 25 passed the Kármán Line, becoming the first Starship to reach space, and also became the heaviest object to ever reach space, before exploding at 148 km. On March 14, 2024, Ship 28 and Booster 10 lifted off the launch pad, successfully achieving its second hot-stage separation, as well as a full-duration ascent burn of the second stage. S28 then proceeded to reenter Earth's atmosphere at orbital velocity, disintegrating during reentry 49 minutes after launch. In April 2024, Elon Musk announced two new versions of Starship, Starship V2 and Starship V3. Both versions will be taller and will have increased thrust.

History

In November 2005, before SpaceX had launched its first rocket the Falcon 1, CEO Elon Musk first mentioned a high-capacity rocket concept able to launch 100 tons to low Earth orbit, dubbed the Big Falcon Rocket (BFR). Later in 2012, Elon Musk first publicly announced plans to develop a rocket surpassing the capabilities of their existing Falcon 9. SpaceX called it the Mars Colonial Transporter, as the rocket was to transport humans to Mars and back.

In 2016, Musk changed the name to Interplanetary Transport System, as he planned for the rocket to travel beyond Mars. Made of carbon fiber, this design was to mass over 10,000 tons when fueled and carry 300 tonnes to low Earth orbit, while intending to be fully reusable. By 2017, the rocket was temporarily re-dubbed the BFR and had multiple variants announced, such as cargo, tanker and crew. In 2019, the current stainless-steel design was adopted.

Design

The current version 1 (V1) of the Starship spacecraft is 50.3 m (165 ft) tall, 9 m (30 ft) in diameter, and has 6 Raptor engines, 3 of which are optimized for use in outer space. The future version 3 (V3) of the Starship spacecraft is planned to have an additional 3 Raptor Vacuum engines for increased payload capacity. Starship V1's payload bay, measuring 17 m (56 ft) tall by 8 m (26 ft) in diameter, is the largest of any active or planned launch vehicle; its internal volume of 1,000 m3 (35,000 cu ft) is slightly larger than the International Space Station's pressurized volume. SpaceX will also provide a 22 m (72 ft) tall payload bay configuration for even larger payloads.

Starship has a total propellant capacity of 1,200 t (2,600,000 lb) across its main tanks and header tanks. The header tanks are better insulated due to their position and are reserved for use to flip and land the spacecraft following reentry. A set of reaction control thrusters, which use the pressure in the fuel tank, control attitude while in space.

The spacecraft has four body flaps to control the spacecraft's orientation and help dissipate energy during atmospheric entry, composed of two forward flaps and two aft flaps. According to SpaceX, the flaps replace the need for wings or tailplane, reduce the fuel needed for landing, and allow landing at destinations in the Solar System where runways do not exist (for example, Mars).: 1 Under the forward flaps, hardpoints are used for lifting and catching the spacecraft via mechanical arms. The flap's hinges are sealed in aero-covers because they would otherwise be easily damaged during reentry.

Starship's heat shield, composed of thousands of hexagonal black tiles that can withstand temperatures of 1,400 °C (2,600 °F), is designed to be used many times without maintenance between flights. The tiles are made of silica and are attached with pins rather than glued, with small gaps in between allowing for heat expansion. Their hexagonal shape facilitates mass production and prevents hot plasma from causing severe damage to the vehicle.

Variants

For satellite launch, Starship will have a large cargo door that opens to release payloads and close upon reentry instead of a more conventional jettisonable nosecone fairing. Instead of a cleanroom, payloads are integrated directly into Starship's payload bay, which requires purging the payload bay with temperature-controlled ISO class 8 clean air. To deploy Starlink satellites, the cargo door will be replaced with a slot and dispenser rack, whose mechanism has been compared to a Pez candy dispenser.

Crewed Starship vehicles would replace the cargo bay with a pressurized crew section and have a life-support system. For long-duration missions, such as crewed flights to Mars, SpaceX describes the interior as potentially including "private cabins, large communal areas, centralized storage, solar storm shelters, and a viewing gallery". Starship's life support system is expected to recycle resources such as air and water from waste.

Starship Human Landing System (HLS) is a crewed lunar lander variant of the Starship vehicle that is extensively modified for landing, operation, and takeoff from the lunar surface. It features modified landing legs, a body-mounted solar array, a set of thrusters mounted mid-body to assist with final landing and takeoff, two airlocks, and an elevator to lower crew and cargo onto the lunar surface. Starship HLS is expected to be able to land more than 100 t (220,000 lb) of payload on the Moon per flight.

Starship will be able to be refueled by docking with separately launched Starship propellant tanker spacecraft in orbit. Doing so would increase the spacecraft's mass capacity and allow it to reach higher-energy targets, such as geosynchronous orbit, the Moon, and Mars. A Starship propellant depot could cache methane and oxygen on-orbit and be used by Starship HLS to replenish its fuel tanks.

Development

Starship's development is iterative and incremental, using frequent—and often destructive—tests on a series of rocket prototypes.

SpaceX prototypes are subjected to several tests before they can be launched. Pressure tests come first, during which the tanks are filled with a liquid or gas to test their strength and safety factor. SpaceX tests some tanks beyond the specified limit, to find the point at which they burst. After engine installation, vehicles undergo static fire testing, during which the engines fire while the vehicle is prevented from lifting off. After passing these tests, a prototype vehicle will launch, either flying within the atmosphere, or attempting to reach orbit.: 15–19

Starhopper

Construction on the initial steel test article—Starship Hopper, Hopper, Hoppy, or Starhopper—began at Boca Chica in 2018. Starhopper had a single engine and was test flown to develop landing and low-altitude/low-velocity control algorithms.

Starhopper used liquid oxygen (LOX) and liquid methane fuel. Starhopper was repurposed after it completed its testing campaign as a water tank, weather station and equipment mount, it was outfitted with cameras, lights, loudspeakers and a radar system.

Testing

It passed tanking tests, wet dress rehearsals, and pre-burner tests. A storm blew over and damaged Starhopper's nose cone. SpaceX continued testing without one.

It then passed a static fire test, and in a tethered test reached 1 meter altitude. On July 25, 2019 a Starhopper test flight reached about 20 m (66 ft) altitude, followed by an August 27 test that rose to 150 m (490 ft) and landed about 100 m (330 ft) from the launchpad, the Raptor's first use in flight.

Mark series (Mk1–Mk4)

SpaceX began building the high-altitude prototype, Mk1 in Texas and Mk2 in Florida, using competing teams that shared progress, insights, and build techniques. The vehicle featured three Raptor methalox engines and were meant to reach an altitude 5 km (3.1 mi).

Mk1 was 9 m (30 ft) in diameter and about 50 m (160 ft) tall, with an empty mass of 200 t (440,000 lb). It was intended for testing flight and reentry profiles, in pursuit of a suborbital flight. When announced, it had three sea-level Raptors, two fins each at the front and back, and a nose cone containing cold-gas reaction control thrusters, with all but the aft fins being removed afterwards.

On November 20, 2019, Mk1 blew apart during a pressure test.

SpaceX began Mk2 in Florida, sharing progress, insights, and build techniques with the Mk1 team in Texas. It was never completed.

The Mk3 prototype began construction in late 2019. In December 2019, Musk redesignated Mk3 as Starship SN1, and predicted that minor design improvements would continue through SN20. SpaceX began stacking SN1 in February 2020 after successful pressurization tests on propellant tank prototypes. SN1 was destroyed during a cryogenic pressurization test on February 28, 2020, due to a design flaw in the lower tank thrust structure.

Mk4 began construction in Florida in October 2019, but was scrapped after a few weeks.

Hops (SN3–SN6)

SN3 and SN4

SN3 was destroyed during testing on April 3, 2020 due to a failure in the testing configuration.

SN4 passed cryogenic pressure testing on April 26 and two static fires on May 5 and May 7: one tested the main tanks, while the other tested the fuel header tank. After uninstalling the engine, a new cryogenic pressure test was conducted on May 19. A leak in the methane fuel piping ignited, causing significant damage to the rocket's base, destroying the control wiring. SN4 was destroyed on May 29, due to a failure with the Ground Support Equipment's quick-disconnect function.

SN5 and SN6

After a static fire test on July 30, SN5 completed a 150-meter flight (August 4) with engine SN27. SN5 was scrapped in February 2021.

SN6 completed a static fire on August 24, and a 150-meter hop test flight with engine SN29 on September 3. In January 2021, SN6 was scrapped.

High-altitude test flights (SN8–S23)

SN8 and SN9

SN8 was planned to be built out of 304L stainless steel, although some parts may have used 301L steel. In late October and November, SN8 underwent four static fires. During the third test, on November 12, 2020, debris from the pad caused the vehicle to lose pneumatics. Launch took place on December 9. Launch, ascent, reorientation, and controlled descent were successful, but low pressure in the methane header tank kept the engines from producing enough thrust for the landing burn, destroying SN8 on impact.

On December 11, the stand beneath SN9 failed, causing the vehicle to tip and contact the walls inside the High Bay. SN9 then required a replacement forward flap. SN9 conducted 6 static fires in January 2021, including three static fires in one day. After these tests, two engines had to be replaced. After struggling to gain FAA permission, SN9 conducted a 10 km (6.2 mi) flight test on February 2. Ascent, engine cutoffs, reorientation and controlled descent were stable, but one engine's oxygen pre-burner failed, sending SN9 crashing into the landing pad. The landing pad was then reinforced with an additional layer of concrete. After the SN9 failure, all three engines were used to perform the belly flop landing sequence. This offered a failsafe should one fail to ignite.

SN10–SN14

SN10 underwent a cryogenic proof test on February 8, followed by a static fire on February 23. After an engine swap, another static fire was conducted on February 25.

Two launch attempts were conducted on March 3. The first attempt was automatically aborted after one engine produced too much thrust while throttling up. After a 3-hour delay to increase the tolerance, the second attempt landed without exploding. The test ended with a hard landing-at 10 m/s – most likely due to partial helium ingestion from the fuel header tank. Three landing legs were not locked in place, producing a slight lean after landing. Although the vehicle initially remained intact, the impact crushed the legs and part of the leg skirt. Eight minutes later the prototype exploded.

SN11 accomplished a cryogenic proof test on March 12 that included a test of the Reaction control system (RCS), followed by a static fire test on March 15, 2021. Immediately after ignition, the test was aborted. Another static fire attempt led to reports that one of the three engines had been removed for repairs. A replacement engine was installed and a third static fire was attempted on March 26. A 10 km flight test was conducted in heavy fog on March 30. The test included engine cutoffs, flip maneuver, flap control and descent, along with a visible fire on engine 2 during the ascent. Just after the defective engine was re-ignited for the landing burn, SN11 lost telemetry at T+ 5:49 and disintegrated. SN12 through SN14 never launched.

SN15–SN19

SN15 introduced improved avionics software, an updated aft skirt propellant architecture, and a new Raptor design and configuration. A Starlink antenna on the side of the vehicle was another new feature. SN15 underwent an ambient temperature pressure test on April 9, 2021, followed by a cryogenic proof test on April 12, and a header tank cryogenic proof test on April 13. A static fire was conducted on April 26, and a header tank static fire on April 27 followed. A 10 km (33,000 ft) high-altitude flight test was conducted in overcast weather on May 5, achieving a soft touchdown. A small fire near the base started shortly after landing, though this was extinquished. After its engines were removed, it was moved to the Rocket Garden on May 31. On July 26, 2023, SN15 was scrapped.

SN16 and SN17 were scrapped, and SN18 and SN19 were never completed.

SN20/Ship 20–Ship 23

SN20 was the first vehicle with a complete thermal protection system (TPS). SN20 rolled out to the launch mount on August 5, 2021, and was stacked onto Booster 4 for a fit test. FCC filings in May 2021 by SpaceX stated that the orbital flight would launch from Boca Chica. After separation, Starship would enter orbit and around 90 minutes later attempt a soft ocean landing around 100 km off the coast of Kauai, Hawaii. However, S20 was retired in March 2022. As of April 2024, SN20 (Ship 20) remains in the Rocket Garden.

Ship 21 was scrapped before being completed.

Ship 22 moved to the Rocket Garden in late February 2022. It was later scrapped, in favor of using S24 for IFT-1.

Ship 23 was scrapped and partially recycled in Ship 24.

V1 orbital launches (S24–S35)

Ship 24 and Ship 25

Ship 24 was first spotted in November 2021, and made cryogenic proof tests on June 2, 2022, June 6, 2022, and June 7, 2022. On June 9, 2022, Ship 24 was rolled back to the production site for engine installation. On July 5, 2022, Ship 24 was rolled back to the launch site and lifted onto Suborbital Pad B a day later. Ship 24 then conducted a successful spin prime test on July 18, 2022. On July 20, 2022, Ship 24 completed two successful spin prime tests. On July 21, 2022, Ship 24 again conducted two spin prime tests, the first test use one engine, while the second test involved two engines. On July 28, 2022, Ship 24 successfully completed a forward flap test. Ship 24 completed two additional successful spin prime tests on August 8, 2022. It was static fired with two engines on August 9, 2022. On August 24, 2022, Ship 24 successfully completed an ignitor test with all 6 of its engines. On August 25, 2022, Ship 24 went through an additional spin prime test. On September 8, 2022, Ship 24 underwent a six engine static fire test, which damaged around 30 of its 18,000 ceramic tiles. The ship was repaired, and was subsequently stacked on top of Booster 7 in mid-October, before being destacked on October 16, 2022, and restacked on October 20, 2022. On November 8, 2022, Ship 24 was destacked again for static fire tests. On December 15, 2022, Ship 24 conducted a single engine static test fire. On January 9, 2023, Ship 24 was stacked on Booster 7, and then destacked on January 24, 2023. On January 26, 2023, Ship 24 was rolled back to the production site for final TPS work. On March 31, 2023, Ship 24 was rolled to the launch site for the final time before launch. On April 5, 2023, Ship 24 had two lift attempts, the first attempt was aborted, however the second attempt, less than a few hours after the first, was successful. On April 12, 2023, Ship 24 was destacked for flight termination system (FTS) installation before launch. On April 15, 2023, Ship 24 was stacked onto Booster 7 for the final time before launch. On April 20, 2023, it was destroyed in flight along with Booster 7 after spinning out of control.

Ship 25 was a Starship prototype similar to the destroyed Ship 24. It flew on the second Integrated Flight Test with Booster 9 and was the first Starship to pass the Kármán Line and reach space. Like Ship 24, Ship 25 featured a heat shield. A payload bay was also built, but was permanently sealed shut. It was used to test the cryogenic test stands at Massey's. During the third week of May 2023, Ship 25 was moved to the launch site and lifted onto suborbital pad B in preparation for engine testing. On June 21, 2023, Ship 25 performed a successful spin prime test. On June 24, 2023, it was announced that Ship 25 would be the first vehicle to use hot-staging (when the second stage fires its engines while some of the booster's engines are still firing). On June 26, 2023, Ship 25 underwent its first static fire test, igniting all six engines. On August 5, 2023, it was moved to the Rocket Garden for final TPS work. On September 5, 2023, it was moved back to the Orbital Launch Site, followed by stacking onto B9. On September 14, 2023, it was removed from B9. On September 27, 2023, it was lifted back onto B9, before being destacked on October 5, 2023. It was then restacked on October 16, 2023, only to be destacked the next day. This was followed by a restack three days later. On October 24, B9 and S25 completed a WDR. On October 26, 2023, S25 was removed from B9. It was restacked on November 1, 2023, and then destacked on November 2, 2023, followed by FTS installation on November 9, 2023. On November 10, 2023, S25 was stacked onto B9, and then destacked on November 11, 2023. On November 15, 2023, S25 was stacked onto B9 for the Second Integrated Flight Test. Due to a failed grid fin actuator on B9, S25 was destacked on November 16, and restacked on November 17.

On November 18, 2023, Ship 25 was launched atop Booster 9 on the second Integrated Flight Test. Ship 25 successfully separated from Booster 9. Near the end of its burn, a LOX dump started a fire in the engine bay, causing an explosion. The autonomous flight termination system activated, destroying the vehicle.

Ship 26 and 27

Ship 26 is an expendable Starship prototype, lacking heat shield tiles and flaps. Ship 26 also lacks a payload bay door. After several cryogenic tests, S26 was moved to the engine installation stand. In December 2023, S26 was moved to the Rocket Garden. On September 9, 2023, S26 was moved to Suborbital Pad B for static fire testing. S26 then underwent a cryogenic test on October 9, 2023, followed by a preburner test with a single engine nine days later, a first for vehicles equipped with Raptor 2 engines. This was followed by a single engine static fire test on October 20, 2023, simulating a deorbit burn. It was moved back to the Rocket Garden one week later. On December 7, 2023, S26 was placed on an engine stand, and a crane was attached to S26, potentially indicating an imminent scrapping. However, on December 11, 2023, the crane was detached from S26, and S26 was returned to the Rocket Garden. On December 16, 2023, SpaceX crews began welding large steel pieces onto the stack weld connecting S26's payload bay and forward dome sections, likely an attempt to reinforce the payload bay, although it is unclear what the reason behind this reinforcement is, or if this means SpaceX plans to use S26 as a flight article. Additional supports were added on December 20, 2023. S26 was moved into Mega Bay 2 on May 7, 2024, and rolled to the Masseys site on May 8 for static fire stand testing. S26 conducted a cryo test on May 24, followed by a six engine static fire on June 3. On June 12, S26 was moved to the Rocket Garden for scrapping.

Like S26, S27 was an expendable prototype, lacking heat shield tiles. It was the first Ship to have a reinforced payload dispenser. Ship 27 was scrapped on July 20, 2023 after the common dome failed. S27's aft section was then converted into a test article, presumably to test the engine shielding design present on S25. On September 27, 2023, S27 was rolled to the Massey's test site.

Ships 28–32

Ship 28, along with subsequent V1 models, features heat shield tiles as well as reinforced Starlink satellite dispensers. In July 2023, S28 underwent cryogenic testing, before being moved onto the engine installation stand. On August 18, 2023, S28 began to have its engines installed. On November 23, 2023, S28 was moved to the High Bay for TPS work. On December 7, 2023, SpaceX confirmed that S28 would be the next vehicle to fly. On December 14, 2023, S28 was moved to the launch site and lifted onto suborbital Pad B for static fire testing. On December 16, 2023, S28 completed a spin prime test, followed by a six engine static fire test on December 20, 2023. This was followed by a deorbit burn test on December 29, 2023. In early January 2024, S28 was moved back to the production site. On January 25, S28 was briefly removed from the High Bay, before returning after realignment of its SPMTs. On January 27, 2024, S28 was moved to the Sanchez site, where it was lifted onto the Engine Installation Stand. There, at least one engine was replaced on January 31, 2024.

S28 was moved to the Orbital Launch Site for IFT-3 on February 10, 2024, and was stacked onto B10. S28 was then destacked on February 12, 2024, potentially due to an issue with the Vented Interstage. On February 13, 2024, S28 was restacked onto B10. On February 14, 2024, a Wet Dress Rehearsal (WDR) attempt was aborted. A second WDR was attempted on February 16, 2024, and it was also aborted. On February 18, 2024, S28 was destacked, and on February 19, it was lifted onto Suborbital Pad B. It underwent a spin prime test on February 26, 2024, before being removed from Suborbital Pad B on February 28, 2024. S28 was stacked on B10 on March 1, 2024. On March 3, 2024, B10 and S28 completed a WDR. On March 5, 2024, S28 was destacked for FTS arming. The FTS was armed on March 8, 2024, followed by S28 being restacked on March 10, 2024. S28 flew with B10 on March 14, 2024, and reached orbit. It conducted tests of the Payload Dispenser and fuel transfer system, before being destroyed during reentry.

On September 22, 2023, S29 was moved to Masseys for cryogenic testing, where it was cryogenically tested on September 26, 2023. On October 13, 2023, S29 was temporarily moved to the Rocket Garden. On November 21, 2023, S29 was moved into the High Bay. In late December, 2023, S29 was moved into Mega Bay 2. It was returned to the High Bay in late February 2024. On February 29, S29 was moved to the launch site, and was lifted onto Pad B on March 2, 2024. S29 underwent a cryogenic test on March 7, 2024, followed by a spin prime test on March 11, 2024. On March 12, 2024, S29 was removed from Suborbital Pad B, followed by a rollback to the production site. On March 22, 2024, it was moved back to the launch site, before being lifted onto Suborbital Pad B for static fire testing. On March 25, 2024, Ship 29 conducted a six engine static fire test. A single engine static fire test was conducted on March 27, 2024. On March 28, it was removed from Pad B, before being returned to the High Bay for Pre-flight modifications. S29 was moved into Mega Bay 2 on May 10.

On May 11, S29 was moved to the Orbital Launch Site for IFT-4. It was lifted onto B11 on May 15, with the combined vehicle completing a partial Wet Dress Rehearsal on May 16. A full Wet Dress Rehearsal was conducted on May 20, followed by S29 being destacked for additional tile work on May 21. It was restacked on May 26, followed by a second Wet Dress Rehearsal on May 28. Ship 29 was destacked on May 29 for final tile work and Flight Termination System (FTS) installation, with FTS installation occurring on May 30. S29 was restacked on June 1, followed by a third destack on June 4. S29 was stacked onto B11 for the fourth and final time on June 5. On June 6, S29 was launched with B11 on IFT-4, with S29 completing a full ascent burn with 0 engine failures. It retained attitude control into reentry, despite the near-complete loss of a forward flap, and achieved a successful landing burn. As of June 8, S29 is the largest artificial object to reenter Earth's atmosphere.

S30 was removed from the High Bay on November 22, 2023. On November 23, 2023, S30 was moved to the High Bay. S30 was moved to Massey's for cryogenic testing on December 30, 2023. On January 3, 2024, S30 underwent its first cryogenic test. On January 10, S30 was returned to the High Bay. It was moved into Mega Bay 2 on April 4, 2024, before being lifted onto Engine Installation Stand 2. The engines were installed between April 8 and April 9, 2024. On May 1, 2024, it was rolled to the Suborbital Launch Site, where it was lifted onto Suborbital Pad B for static fire testing. It conducted a cryogenic test on May 7, followed by an aborted static fire test. On May 8, it completed a 6 engine static fire test, which was also the last static fire to be conducted at the Suborbital Launch Site. It was removed from Pad B on May 10, before being rolled to the production site. S30 was moved into the High Bay on May 11. On June 5, at least one RVAC was replaced for unknown reasons. On June 9, Musk claimed that SpaceX would be replacing S30s entire heat shield as a result of data gathered from IFT-4, with an ablative heat shield underneath for secondary protection. The removal of Thermal Protection System tiles began on June 11.

On December 14, 2023, S31 was moved to the Rocket Garden, before being moved back into the High Bay on January 4. It was rolled to Masseys for cryogenic testing on May 11. As of May 11, 2024, S31 is expected to be the first flight vehicle to static fire stand at Masseys. On May 12, S31 conducted a cryogenic test, ending prematurely due to an electrical anomaly. It was rolled back to the production site for repairs on May 15. On July 1, it returned to Masseys for cryogenic testing. It was cryo tested on July 2 and July 3.

On November 24, Elon Musk stated that S32 would be the last V1 starship. On January 10, 2024, S32 was moved to the Rocket Garden. On June 21, the FCC confirmed that Flight 7 would use a v2 vehicle.

Ships 33–35

In late November, 2023, S33's components were scrapped, alongside the components of S34 and S35.

V2 orbital launches (S36 and subsequent)

As of July 2024, parts of S36 and S37 have been spotted. The V2 ships will feature a new forward flap design, increased propellant capacity, and an increase in thrust. These vehicles will be a total of 1.8 m (5 ft 11 in) meters taller than the previous V1 ships.

Test articles

Starship-based test articles

Liquid Oxygen Header Test Tank (LOX HTT) was based on the LOX Header tank, as well as surrounding parts of the nosecone. On January 24, 2020, the tank underwent a pressurization test which lasted several hours. The following day it was tested to destruction.

SN2 was a test tank used to test welding quality and thrust puck design. The thrust puck is found on the bottom of the vehicle where in later Starship tests up to three sea-level Raptor engines would be mounted. SN2 passed a pressure test on March 8, 2020.

SN7 was a pathfinder test article for the switch to type 304L stainless steel. A cryogenic proof test was performed on June 15, 2020, achieving a pressure of 7.6 bar (110 psi) before a leak occurred. During a pressurize to failure test on June 23, 2020, the tank burst at an unknown pressure.

SN7.1 was the second 304L test tank, with the goal of reaching a higher failure pressure. The tank was repeatedly tested in September, and tested to destruction on September 23. The bulkhead came apart at a pressure of 8 bar (115 psi) in ullage and 9 bar (130 psi) at base.

SN7.2 was created to test thinner walls, and therefore, lower mass. It is believed to be constructed from 3 mm steel sheets rather than the 4 mm thickness of its predecessors. On January 26, 2021, SN7.2 passed a cryogenic proof test. On February 4, during a pressurize to failure test, the tank developed a leak. On March 15, SN7.2 was retired.

S26.1 was a test tank designed to test the aft section of ships after S24. It conducted two tests on the can-crusher, before being moved off in July 2023. On September 21, 2023, it was tested to destruction.

S24.2 was a test article designed to test the payload bay of Starlink dispenser vehicles. On September 28, 2023, it was moved to the Masseys test site. It preformed two tests before subsequently being scrapped.

General test articles

Test Tank 1 (TT1) was a subscale test tank consisting of two forward bulkheads connected by a small barrel section. TT1 was used to test new materials and construction methods. On January 10, 2020, TT1 was tested to failure as part of an ambient temperature test, reaching a pressure of 7.1 bar (103 psi).

Test Tank 2 (TT2) was another subscale test tank similar to TT1. On January 27, 2020, TT2 underwent an ambient temperature pressure test where it reached a pressure of 7.5 bar (109 psi) before a leak occurred. Two days later, it underwent a cryogenic proof test to destruction, bursting at 8.5 bar (123 psi).

GSE 4.1 was first spotted in August 2021 and was the first ground support equipment (GSE) test tank built, made from parts of GSE 4. It underwent a cryogenic proof test on August 2023 before it was rolled to Sanchez site. It was rolled back to the launch site in November 2021, where it underwent an apparent cryogenic proof test to failure on January 18, 2022, where it burst at an unknown pressure.

EDOME was a test tank created to test flatter domes, possibly used on future Starship prototypes. It was moved to the launch site in July 2022, and then back to the production site the next month, after undergoing no tests. It was later moved from the production site to the Massey's test site in late September 2022, where it was damaged during a cryogenic pressure test to failure. After repairs, it was tested to destruction in late October 2022.

EDOME 2 was a test tank which is likely designed to continue testing a flatter dome design. As of October 4, 2023, its official designation is unknown. It was tested once, before being scrapped for unknown reasons.

See also

- Artemis Program

- New Glenn

- Falcon Heavy

- Private spaceflight

- SpaceX Super Heavy

- Space Shuttle orbiter

- Timeline of space exploration

References

Text submitted to CC-BY-SA license. Source: SpaceX Starship (spacecraft) by Wikipedia (Historical)

Articles connexes

- SpaceX Starship

- SpaceX Starship flight tests

- Starship HLS

- SpaceX Starship integrated flight test 2

- SpaceX Starship design history

- SpaceX Starship integrated flight test 3

- SpaceX Dragon

- SpaceX Mars Colonization Program

- SpaceX Starship integrated flight test 1

- DearMoon project

- SpaceX Raptor

- SpaceX Starship integrated flight test 4

- SpaceX

- SpaceX Starbase

- Reusable spacecraft

- SpaceX reusable launch system development program

- SpaceX Starship integrated flight test 6

- SpaceX Starship integrated flight test 5

- SpaceX Super Heavy

- SpaceX Red Dragon

Owlapps.net - since 2012 - Les chouettes applications du hibou